In liquid column

Storyboard

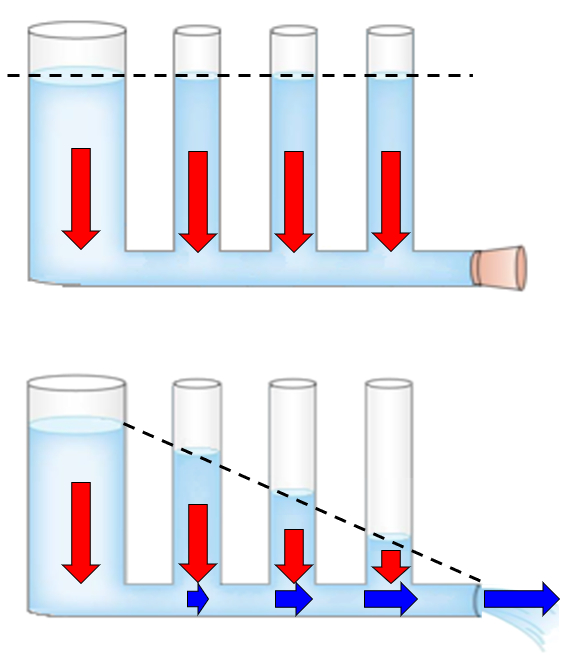

In the case of a column of liquid, Bernoulli's law can be applied along with the hydrostatic pressure term. However, it's important to note that when viscosity of the liquid is not considered, the reduction in level occurs uniformly. In this regard, it can be modeled using the continuity equation to determine the downward velocity of the cylinder.

For a column of liquid with an outlet at the bottom, the behavior is similar to what is estimated with Bernoulli's principle. Differences arise due to the formation of small vortices at the outlet, effectively reducing the outlet area and obstructing the flow. However, the flow of a low-viscosity liquid can be modeled in the zone without vortices using Bernoulli's principle.

ID:(1427, 0)

In liquid column

Storyboard

In the case of a column of liquid, Bernoulli's law can be applied along with the hydrostatic pressure term. However, it's important to note that when viscosity of the liquid is not considered, the reduction in level occurs uniformly. In this regard, it can be modeled using the continuity equation to determine the downward velocity of the cylinder. For a column of liquid with an outlet at the bottom, the behavior is similar to what is estimated with Bernoulli's principle. Differences arise due to the formation of small vortices at the outlet, effectively reducing the outlet area and obstructing the flow. However, the flow of a low-viscosity liquid can be modeled in the zone without vortices using Bernoulli's principle.

Variables

Calculations

Calculations

Equations

If there is the pressure difference ($\Delta p$) between two points, as determined by the equation:

we can utilize the water column pressure ($p$), which is defined as:

This results in:

$\Delta p=p_2-p_1=p_0+\rho_wh_2g-p_0-\rho_wh_1g=\rho_w(h_2-h_1)g$

As the height difference ($\Delta h$) is:

the pressure difference ($\Delta p$) can be expressed as:

Using Bernoulli's equation, we can analyze the case of a column of water that generates a pressure difference:

and induces a velocity flow $v$ through a tube, in accordance with:

Thus, we can estimate the velocity as:

$v = \sqrt{2 g h}$

This velocity, through a tube section of radius $R$, results in a flow:

$J = \pi R^2 v$

If the column has a cross-sectional area $S$, and its height decreases with respect to the variation in height $h$ over time $t$, we can apply the law of continuity, which states:

Therefore, the equation that describes this situation is:

If in the equation

the constants are replaced by

we obtain the first-order linear differential equation

$\displaystyle\frac{dh}{dt}=\displaystyle\frac{1}{\tau_b} \sqrt{h_0 h}$

whose solution is

In this case, it can be assumed that the mean Speed of Fluid in Point 2 ($v_2$) represents zero velocity and the mean Speed of Fluid in Point 1 ($v_1$) corresponds to the flow speed ($v_s$). Therefore, for the speed difference between surfaces ($\Delta v$) the following is established:

$\Delta v = v_2 - v_1 = 0 - v_s = - v_s$

and for the average speed ($\bar{v}$) it is calculated:

$\bar{v} = \displaystyle\frac{v_1 + v_2}{2} = \frac{v_s}{2}$

Consequently, with the variación de la Presión ($\Delta p$), which equals the pressure difference ($\Delta p_s$), we obtain:

resulting in:

$\Delta p_s = \displaystyle\frac{1}{2} \rho v_s^2$

leading to:

The volume ($V$) for a tube with constant the section Tube ($S$) and a position ($s$) is

If the section Tube ($S$) is constant, the temporal derivative will be

$\displaystyle\frac{dV}{dt} = S\displaystyle\frac{ds}{dt}$

thus, with the volume flow ($J_V$) defined by

and with the flux density ($j_s$) associated with the position ($s$) via

it is concluded that

Examples

If there is a column height ($h$) of liquid with the liquid density ($\rho_w$) under the effect of gravity, using the gravitational Acceleration ($g$), the variación de la Presión ($\Delta p$) is generated according to:

This the variación de la Presión ($\Delta p$) produces a flow through the outlet tube with the tube length ($\Delta L$), the tube radius ($R$), and the viscosity ($\eta$) of a volume flow 1 ($J_{V1}$) according to the Hagen-Poiseuille law:

Since this equation includes the section in point 2 ($S_2$), the flux density 2 ($j_{s2}$) can be calculated using:

With this, we obtain:

which corresponds to an average velocity.

To model the system, the key parameters are:

• Interior diameter of the container: 93 mm

• Interior diameter of the evacuation channel: 3.2 mm

• Length of the evacuation channel: 18 mm

The initial liquid height is 25 cm.

Let's consider the system of a cylindrical bucket with a drainage hole. When the plug is removed, the water starts to flow due to the existing pressure. According to Bernoulli's principle, inside the bucket ($v\sim 0$), the velocity is zero, and we have:

$\displaystyle\frac{1}{2}\rho v^2 + \rho g h\sim \rho g h$

while outside the bucket ($h=0$), only the kinetic component exists:

$\displaystyle\frac{1}{2}\rho v^2 + \rho g h\sim \displaystyle\frac{1}{2}\rho v^2$

Since both expressions are equal, we have:

$\displaystyle\frac{1}{2}\rho v^2=\rho g h$

which gives the velocity as:

$v=\sqrt{2 g h}$

To compare with the experiment, we can use this expression to estimate, with:

the range that the stream should have. If we plot it graphically, we observe:

where:

• the red dots correspond to the experimental measurements,

• the blue dots correspond to the calculated range using a factor of 0.11,

• the transparent dots correspond to the calculated range using a factor of 0.09.

Therefore, we can conclude that Bernoulli's model overestimates the velocity at which the bucket empties. This is because in the vicinity of the drainage hole, the effects of viscosity are not negligible, and therefore, the velocity is lower.

If the Tracker program is used, the height of the meniscus of the column and the range of the jet can be measured. The relationship between the two is shown in the following graph:

The recorded data, which can be downloaded as an Excel table from the following link excel table, are as follows:

| Time [s] | Height [m] | Reach [m] |

| 0 | 2.23E-01 | 1.89E-01 |

| 4 | 2.14E-01 | 1.86E-01 |

| 8 | 2.04E-01 | 1.82E-01 |

| 12 | 1.94E-01 | 1.77E-01 |

| 16 | 1.86E-01 | 1.72E-01 |

| 20 | 1.79E-01 | 1.68E-01 |

| 24 | 1.71E-01 | 1.66E-01 |

| 28 | 1.63E-01 | 1.62E-01 |

| 32 | 1.54E-01 | 1.58E-01 |

| 36 | 1.46E-01 | 1.52E-01 |

| 40 | 1.39E-01 | 1.48E-01 |

| 44 | 1.32E-01 | 1.44E-01 |

| 48 | 1.24E-01 | 1.39E-01 |

| 52 | 1.18E-01 | 1.35E-01 |

| 56 | 1.11E-01 | 1.31E-01 |

| 60 | 1.06E-01 | 1.27E-01 |

| 64 | 9.88E-02 | 1.23E-01 |

| 68 | 9.29E-02 | 1.18E-01 |

| 72 | 8.70E-02 | 1.15E-01 |

| 76 | 8.11E-02 | 1.12E-01 |

| 80 | 7.52E-02 | 1.06E-01 |

| 84 | 7.12E-02 | 1.02E-01 |

| 88 | 6.51E-02 | 9.69E-02 |

| 92 | 6.00E-02 | 9.42E-02 |

| 96 | 5.58E-02 | 8.94E-02 |

| 100 | 5.09E-02 | 8.52E-02 |

| 104 | 4.70E-02 | 8.13E-02 |

| 108 | 4.34E-02 | 7.63E-02 |

| 112 | 3.97E-02 | 7.22E-02 |

| 116 | 3.49E-02 | 6.79E-02 |

| 120 | 3.15E-02 | 6.28E-02 |

| 124 | 2.91E-02 | 5.96E-02 |

| 128 | 2.58E-02 | 5.33E-02 |

| 132 | 2.23E-02 | 4.92E-02 |

| 136 | 1.98E-02 | 4.31E-02 |

| 140 | 1.71E-02 | 3.85E-02 |

| 144 | 1.54E-02 | 3.38E-02 |

| 148 | 1.28E-02 | 2.85E-02 |

| 152 | 1.11E-02 | 2.23E-02 |

| 156 | 9.17E-03 | 1.54E-02 |

| 160 | 7.15E-03 | 7.95E-03 |

Note: E indicates scientific notation (ej. 1.2E+3 = 1.2x10^3 = 1200, y 1.2E-3 = 1.2x10^-3 = 0.0012)

If we have a tube with a the section Tube ($S$) moving a distance the tube element ($\Delta s$) along its axis, having displaced the volume element ($\Delta V$), then it is equal to:

The volume flow ($J_V$) corresponds to the volume flowing ($\Delta V$) flowing through the channel at the time elapsed ($\Delta t$). Therefore, we have:

The flux density ($j_s$) is related to the distance traveled in a time ($\Delta s$), which is the distance that the fluid travels in the time elapsed ($\Delta t$), as follows:

A flux density ($j_s$) can be expressed in terms of the volume flow ($J_V$) using the section or Area ($S$) through the following formula:

The surface of a disk ($S$) of ERROR:5275.1 is calculated as follows:

When applying the Bernoulli equation relative to a stationary point in the flow, it is established that the flow speed ($v_s$) is associated with the pressure difference ($\Delta p_s$) concerning the pressure at this point. With the density ($\rho$), the following is observed:

The height difference, denoted by the height difference ($\Delta h$), implies that the pressure in both columns is distinct. In particular, the pressure difference ($\Delta p$) is a function of the liquid density ($\rho_w$), the gravitational Acceleration ($g$), and the height difference ($\Delta h$), as follows:

The principle of continuity dictates that the flow at the first point, which is equal to the flux density 1 ($j_{s1}$) times the section in point 1 ($S_1$), must be equal to the flow at the second point, given by the flux density 2 ($j_{s2}$) times the section in point 2 ($S_2$). From this, it follows that:

For the case of a non-viscous liquid flowing in a laminar fashion, the pressure difference generated by the column is:

This results in a velocity flow $v$ through a tube according to Bernoulli's principle:

Given the velocity and the tube's radius, we can calculate the flow, which is related to the flow within the column through the law of continuity. In turn, this is connected to the variation in height $h," as described in:

If we examine the equation for the draining of a non-viscous liquid column:

we can condense the constants into a characteristic time unit:

This value becomes the time it takes for the column to completely empty, and it depends on the initial height.

The equation describing the evolution of the draining viscous liquid column is as follows:

We can rewrite this equation in terms of the characteristic time:

Upon integrating, we obtain:

Where $h_0$ represents the initial height.

ID:(1427, 0)